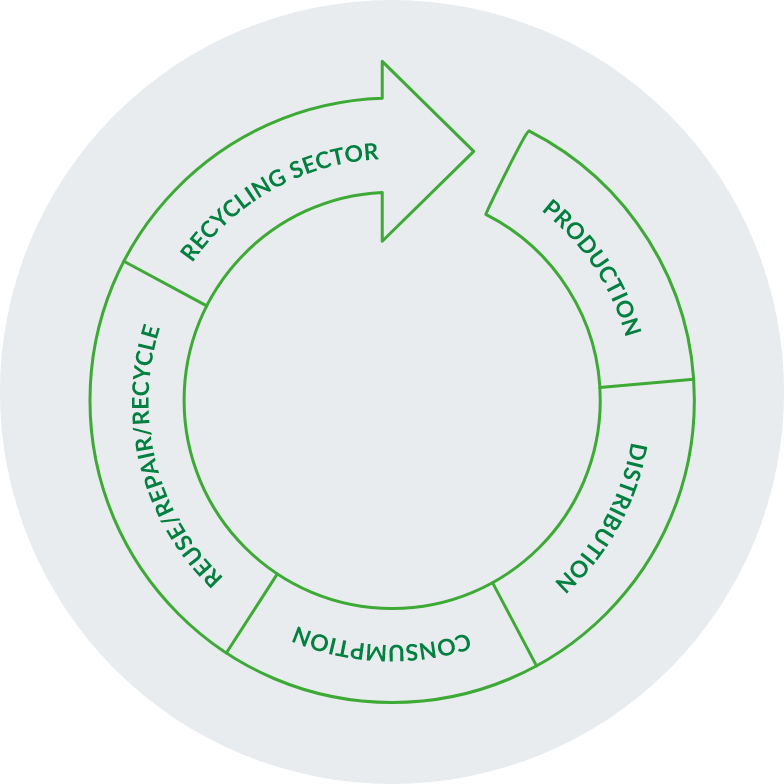

Based on the alarming global situation and with the raise in environmental concern, the EU commission has set the European Plastic Strategy which is aimed at tackling the plastic waste issues and fixes ambitious objectives for both industry and brands. From increasing percentage of recyclable material to be used in packaging (50% by 2025 and 55% by 2030) to the ban on micro plastics, the rules relating to the use of plastic packaging are numerous, complex and can vary from country to country. Main goal is to reach a circular economy in 2050; preventing packaging waste, boosting reuse and refill and making all plastic packaging by 2030 reusable, recyclable or compostable.

The EU is also considering the use of financial incentives to encourage brands to use sustainable packaging whilst extra charges could be incurred by those brands using poorly recyclable solutions. This has already been put into place in the UK in 2022 (Plastic Packaging Tax), Spain (2023) and Italy is expected to follow in 2024.

The EU is proposing new EU-wide rules on packaging, to tackle the constantly growing source of waste. For consumers they will ensure reusable packaging options, reduce unnecessary packaging, limit over packaging, and provide clear labels to support correct recycling.

For the industry they want to decrease the need for virgin materials and boosting Europe’s recycling capacity to make Europe less dependent on primary resources and external suppliers. Producers need to take more responsibility in designing new plastic packaging which is reusable, recyclable and with mandatory rates of recycled content. Manufacturers are held responsible for the entire lifecycle of a product. This includes recycling and take-back programs to ensure that goods are properly disposed.

The influx of information can become confusing and that’s why, at Pont, we are committed to bringing full support and assistance to our customers in this area.

From the complete existing packaging assessment to the design of the most suitable and sustainable solution, we will help you to respect the new rules and to avoid unnecessary penalties on non-sustainable packaging.